Introduction

Packaging engineers today work under unavoidable commercial pressure: protect product integrity, lower total delivered cost, and prove measurable sustainability gains. For years, these performance targets demanded compromise: weight reduction typically sacrificed structural integrity, higher strength introduced undesirable bulk, and recyclable formats often carried a cost penalty.

Paper honeycomb has changed that equation. Once viewed as a niche, application-specific material, it has now entered the mainstream packaging as it delivers structural performance through geometry rather than material mass. In doing so, it meets engineering, commercial and sustainability objectives simultaneously.

Paper Honeycomb: An Overview

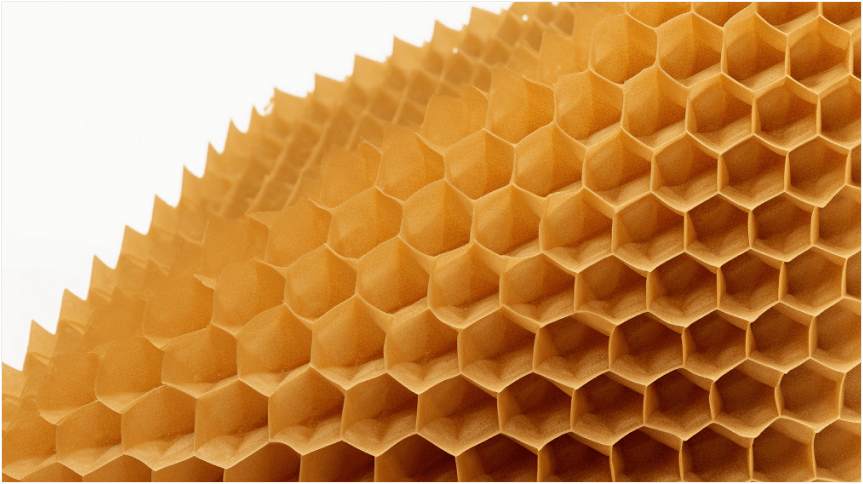

Paper honeycomb is made by bonding long strips of paper together and then expanding them to create a pattern of hexagonal cells (similar to a beehive). This core is then placed between two flat sheets of paper called face sheets. Once laminated, the result is a light, rigid board that can be cut, folded and glued just like corrugated. It can be produced in different cell sizes, thicknesses and paper grades, and is used to make top-load pads, edge protectors, crates, snug-fit packaging cushions, filler blocks and pallet decks.

The Science Behind Honeycomb’s Strength:

The strength of honeycomb comes from the shape, not the amount of material. When honeycomb is sandwiched between two facings, it behaves like a strong beam: the face sheets take the tension and puncture resistance, while the core gives it compressive strength, stopping the structure from bending or buckling. Under stacking loads, each honeycomb cell acts like a small column, allowing it to carry heavy weight. During transport, the structure also absorbs impact, helping protect products from shocks.

Four Simple Factors Control Performance:

- Smaller cells make the board stiffer.

- Heavier face paper increases strength and puncture resistance.

- Thicker cores improve bending strength.

- Strong bonding prevents layers from separating.

Global Adoption in Load-Bearing Applications:

This engineering advantage is why honeycomb is moving rapidly into heavy-load and high-value packaging. Automotive parts, home appliances, industrial equipment, machinery and machine components, Aerospace components, electrical components, flat-pack furniture and white goods now use honeycomb panels for pallets, corner blocks and crates. In these applications, honeycomb replaces timber, MDF, foam of various types, EPS and plastic-based boards while offering equal stack loads, lower shipping mass and full recyclability.

In export logistics, where every kilogram affects freight cost, honeycomb pallets are increasingly selected purely for the mass reduction they deliver. The shift to honeycomb is no longer experimental. It is commercial and global.

Addressing Engineering Pain Points:

Engineers often raise the same three concerns: moisture, creep under sustained load, and puncture at exposed edges. All three are known behaviours of fibre-based structures, and all are manageable through the honeycomb’s design. Moisture sensitivity is reduced with water-resistant liners, barrier facings and edge sealing. Long-term creep is mitigated by correct safety factors, higher grammage papers, and load paths that avoid permanent shear.

Puncture risk is addressed through tougher facings or reinforcement at exposed edges and corners. In practice, failures occur when panels are underspecified. When designed and tested with the same discipline applied to other sandwich structures, honeycomb performs reliably and predictably.

Engineering Guidelines for Honeycomb Structures:

Designing successfully with honeycomb requires the same discipline used for composites: define load cases, calculate bending stiffness with sandwich theory, and use FEA when local effects dominate. Early prototyping is essential because facings, edge closures and adhesive systems govern real-world behaviour as much as the core itself.

Many of the biggest cost reductions come not from the core, but from removing over-engineered elements around it. Extracting those gains is not a generic skill set, as it demands manufacturers who understand how to engineer the packaging concerning the entire system, not just supply materials.

Honecore’s Engineered Solution:

Honecore is one of India’s longest-serving paper honeycomb specialists, delivering engineered protective packaging for automotive, shipping, industrial, and other manufacturers.

- With over 18 years of experience, the company replaces heavier, more expensive and less sustainable materials with high-performance honeycomb system.

- Its strength lies in a supply-chain-led engineering process: every design maps product movement, transport modes, handling conditions and real damage scenarios.

- Honecore is also the only honeycomb producer with manufacturing in North, West and South India, ensuring consistent supply, shorter lead times and rapid response during surge demand.

- By providing lighter, stronger and fully recyclable protection, Honecore helps customers cut logistics costs, improve product safety and achieve measurable sustainability gains, turning packaging from a cost centre into a competitive advantage.

Conclusion: The New Reality for Packaging

Expected to reach a $6.46 billion market by 2030, Paper honeycomb has transitioned from an alternative option to a validated structural solution with clear commercial impact in the packaging and exporting industry. When applied with rigour, it reduces transported mass, lowers the bill of materials, and improves sustainability without sacrificing performance. Markets are adopting it because it lets engineers do more with less.

In an environment where every gram, every rupee and every sustainability metric is scrutinised, paper honeycomb is no longer just another material option. It is a competitive lever. From lightweight pallets to export-grade crates, it is enabling companies to ship smarter, greener and more economically. The evidence is clear: honeycomb is not the future of protective packaging. It is the new standard.