Introduction

The industrial packaging sector is entering a pivotal era. Once driven primarily by durability and cost, the market is now reshaping itself around sustainability, circular material use, and logistics efficiency. Recent market analysis shows that the global industrial packaging market is projected to reach USD 111.8 billion by 2034, with sustainability positioned as a primary growth catalyst. The shift has already been adopted by the packaging industry due to regulatory pressure, ESG mandates, and customer procurement policies that have redefined what industrial packaging must deliver.

This blog delves into the shift from traditional packaging priorities to performance-driven sustainability, examining the engineering, compliance and circularity principles now reshaping how industrial supply chains operate.

Sustainability Has Moved From Intention to Inspection

A few years ago, conversations rarely went beyond recyclability labels or broad commitments. But today, industrial buyers speak an entirely different language, centred on CO₂ per shipment, recovery rates, material traceability, and eco-circularity performance. Packaging is no longer treated as a peripheral decision, as it has become a measurable supply-chain indicator that shapes operational risk and commercial credibility. ESG teams now audit it, compliance teams are accountable for it, and procurement teams benchmark it with the same rigour as cost or lead time. What was once a simple checkbox has evolved into a critical performance metric, one where companies are evaluated not by what they promise, but by the quality of the data behind those promises.

The Industry Shift: Replacing Material Complexity With Intelligent Engineering

Popular headlines often simplify the transition as material swaps. The real movement is deeper and more economic: heavy to light, rigid to engineered, mixed-material to mono-material, linear to recoverable. Industries across automotive, engineering goods, electronics and chemicals are making the change because performance metrics are changing:

Four simple factors control performance:

– Lighter systems cut freight emissions.

– Mono-material structures reduce recycling friction.

– Engineered fibre delivers load-bearing strength once exclusive to wood and rigid plastics.

– Recycled polymers meet compliance without overhauling existing processes.

It’s not an environmental compromise but an operational upgrade that delivers measurable financial returns.

Engineering Is Redesigning the Entire Logistics Chain

The engineering shift in packaging is fundamentally performance-first. Teams are now designing structures that stack higher, withstand vibration, manage humidity, and prevent load damage that results in both economic and carbon losses.

Packaging has become a high-performance logistics component, validated for real-world operating stresses such as compression, multi-modal transit shocks and drastic climate variations.

Engineering innovation ensures products arrive safer, faster and with fewer resource inputs. Better logistics performance is now the direct driver of sustainability gains.

Circularity Is Rewriting the Rules of Procurement

Circularity in industrial packaging is no longer defined by returnable systems. Instead, it is now centred on how efficiently raw materials can be recovered, recycled, and reintroduced into production cycles. Fibre-based materials such as kraft paper and engineered honeycomb are becoming preferred choices because they are naturally compatible with high-volume recycling ecosystems.

For procurement teams, circularity now means:

- Choosing mono-material fibre structures that simplify recycling.

- Prioritising materials with high recovery and reintegration rates, such as kraft paper.

- Evaluating packaging by its total lifecycle impact, including end-of-life recyclability and renewable sourcing.

- Selecting engineered fibre systems that reduce waste, improve cube utilisation, and deliver strong compliance scores.

Packaging is now judged not by how many times it can be reused, but by how effectively its material value can be retained and recovered across cycles.

Regulation Has Become the Fastest Catalyst in the System

EPR mandates, landfill restrictions, carbon reporting laws and zero-waste targets are accelerating innovation faster than market forces alone ever did. For instance, under India’s 2025 Plastic Waste Management Rules (Rule 19), companies that fail to comply can face fines ranging from Rs 10,000 to Rs 150,000, plus additional daily penalties for ongoing violations.

This shift is particularly visible in materials like kraft paper and engineered fibre, which benefit from strong recycling infrastructure and high recovery rates. As regulations tighten, fibre-based packaging aligns naturally with EPR frameworks because it is easier to trace, recycle, and certify for compliance. Companies increasingly select renewable, recyclable materials not just for sustainability credentials but to meet statutory expectations with lower compliance risk.

Engineered Fibre: The Unexpected Front-Runner

Engineered fibre, especially kraft-based honeycomb, has emerged as a front-runner because it offers industrial-grade performance while remaining fully recyclable. Unlike complex multi-material systems that create recycling challenges, engineered fibre supports a clean circular economy by enabling high recovery rates and low-carbon end-of-life processing.

Honeycomb delivers:

- Strong compression strength suitable for heavy industrial applications

- Significantly reduced transport weight

- Lower embodied carbon compared with rigid substrates

- Simple, cost-efficient recyclability through existing paper recovery networks

Its ability to combine engineering performance with fibre circularity is reshaping material strategies across sectors.

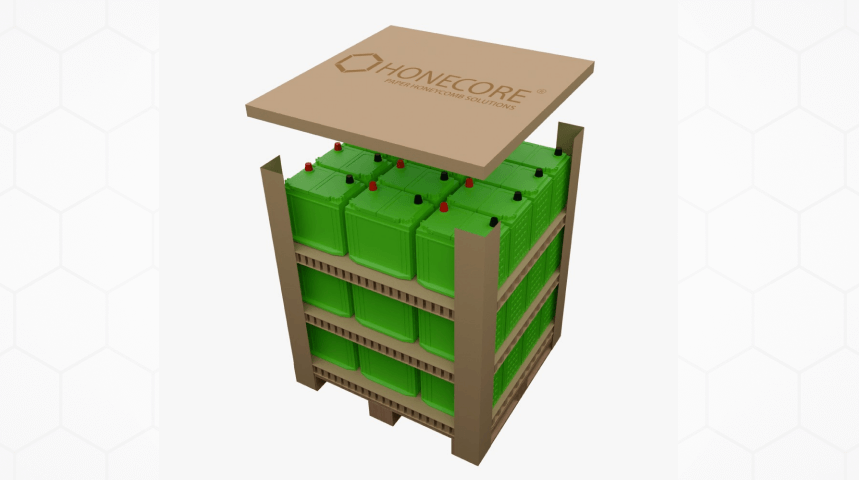

Honecore: Where Engineering Meets Sustainable Performance

For nearly two decades, Honecore has specialised in engineered fibre and honeycomb solutions that help manufacturers reduce damage, optimise logistics, and meet circularity targets rooted in recyclable material use.

Our patented kraft-based systems are designed for real operating environments and validated for product behaviour, transit stresses, warehouse handling, and recovery efficiency. The result is lighter, stronger, fully recyclable packaging that maximises cube utilisation and ensures seamless compliance across global supply chains.

Honecore empowers Indian manufacturers with fibre-first solutions that meet international standards, lower total cost of ownership, and reinforce circularity through renewable, recyclable raw materials.

Conclusion: A Market Reset, Not a Market Trend

The shift in industrial packaging is no longer about environmental intent, as it signals a fundamental reset in how modern supply chains operate. The real leaders in this transition aren’t the loudest. They’re the ones re-engineering materials for performance, cutting carbon through smarter engineering, embedding circularity into commercial models, and treating compliance as a core design input.

Packaging has moved far beyond its traditional role of protection. It has become a strategic sustainability asset, shaping cost, resilience, reliability, and long-term competitiveness. Organisations that understand this shift early won’t just adapt but redefine the next era of industrial logistics.