Introduction

Sustainability in packaging is often discussed in terms of materials alone. Yet in practice, meaningful impact is achieved not by material substitution but by engineering precision. Honecore was founded on this understanding, with a clear objective: to reduce material usage and cost while delivering world-class, sustainable packaging solutions and to ensure uncompromising, end-to-end protection for products throughout their lifecycle.

This engineering-driven mindset continues to define how Honecore designs, validates, and delivers packaging solutions for Indian manufacturers operating in global markets.

Packaging as an Engineering System, Not a Commodity

Traditional packaging development frequently relies on standardised formats, conservative safety margins, and excess material to offset uncertainty. While this approach may offer perceived security, it often results in inflated costs, increased waste, and inefficiencies across logistics and handling.

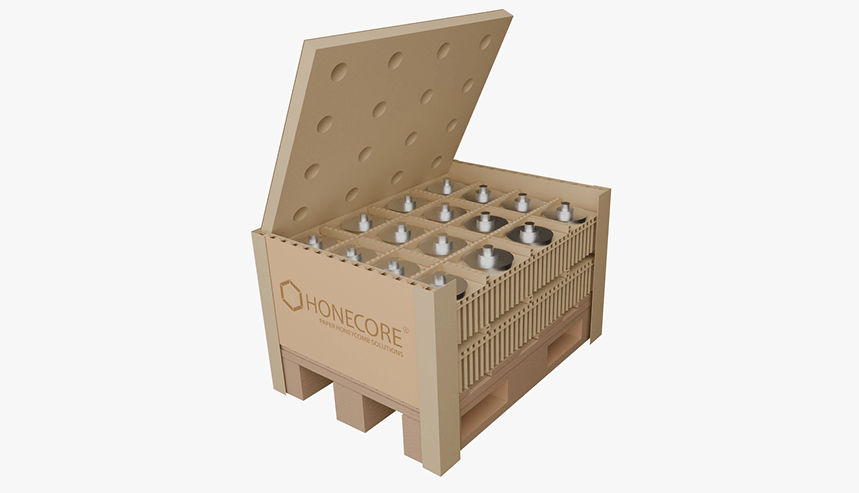

Honecore approaches packaging as a performance-critical engineering system. Each solution is designed through a detailed analysis of the product, its operational environment, and the conditions it will encounter from packing to unpacking. The objective is not to add layers but to optimise structure, geometry, and material placement to achieve functional efficiency with minimal material input.

This methodology allows Honecore to engineer packaging that meets global performance benchmarks while using significantly less material than conventional alternatives.

Supporting Indian Products with Global-Grade Packaging

Indian manufacturers increasingly serve international markets that demand consistency, reliability, and compliance with global packaging standards. However, packaging is often the weakest link, either overdesigned and costly, or under-engineered and prone to failure.

Honecore was established to address this gap by delivering world-class packaging solutions engineered in India, specifically for Indian products. The focus is on enabling manufacturers to protect product integrity, reduce total cost of ownership, and meet global logistics and handling requirements without relying on imported design philosophies or excessive material use.

By combining local manufacturing insight with global engineering standards, Honecore ensures packaging performance aligns with international expectations.

Highly Analysed Engineering: From Product to Process

At the core of Honecore’s approach is a comprehensive engineering analysis that extends beyond the product itself.

Each packaging solution begins with an in-depth study of the product’s physical characteristics, dimensions, weight distribution, fragility, surface sensitivity, and structural behaviour under load. This is followed by an evaluation of the complete logistics chain, including transportation modes, stacking configurations, vibration exposure, compression forces, and environmental conditions.

Equally critical is the unpacking and handling process. Honecore analyses whether packages will be handled manually or by automated systems, the speed and frequency of operations, and the safety and ergonomic requirements involved. These factors directly influence packaging geometry, access points, and structural reinforcements.

By analysing the entire operational ecosystem, Honecore engineers package that which is precisely calibrated to real-world use, eliminating redundancy while maintaining protection.

Material Reduction Without Compromising Protection

One of Honecore’s primary goals is to reduce material usage and associated costs without sacrificing performance. This is achieved through structural optimisation rather than material substitution alone.

Advanced design techniques allow material to be strategically distributed only where load-bearing or impact resistance is required. Areas that do not contribute to performance are systematically removed. The result is packaging that is lighter, more efficient, and easier to handle, while still delivering robust protection.

This reduction in material directly translates into lower raw material consumption, reduced transportation costs, improved stacking efficiency, and a smaller environmental footprint, without increasing risk.

End-to-End Product Protection as a Design Mandate

World-class packaging must perform consistently across every stage of the supply chain. Honecore designs with end-to-end protection as a non-negotiable requirement.

From the moment a product is packed, through storage, transit, automation, and final unpacking, the packaging must maintain structural integrity and product safety. Designs are validated against real handling scenarios to ensure reliability under operational stress.

This focus on lifecycle performance ensures that material reduction never comes at the cost of product damage, returns, or operational disruption.

A Responsible, Measurable Approach to Sustainability

For Honecore, sustainability is not defined by claims, but by outcomes. Reduced material usage, optimised cost structures, and improved logistics efficiency are tangible results of engineering-led design.

By aligning sustainability objectives with performance and cost efficiency, Honecore enables manufacturers to make environmentally responsible choices that also support business objectives. This pragmatic approach ensures sustainability is embedded into operations, not treated as a separate initiative.

Conclusion: The Engineering Mindset That Drives Honecore

Honecore was built on the belief that better packaging is not achieved through excess, but through understanding. Understanding products, processes, and performance requirements in detail allows packaging to be designed with intent and accountability.

By reducing what is unnecessary and reinforcing what matters, Honecore continues to support Indian manufacturers with packaging solutions that are efficient, protective, and globally competitive.

Where sustainability meets engineering, the outcome is not compromise—but precision.